Fire Security coated cable splices with the fire-resistant coating to prevent fire incidents and production shut down.

Fire protection team led by FS Asia manager Paal Mathisen and Eric Wei, local FS agent for Shagang Steel, Jiangsu, China.

The plant is located in Jiangsu province in central China, a few hours’ drive from Shanghai.

Due to the immense size of the plant (10 km2) they had spliced their 15-35 KV main distribution cables. As a result in the last few years, they experienced 3 fire incidents where a fire started from the splices and damaged other industrial cables running beside and above the spliced cables. This had a negative impact on the steel plant with a partial shut down of production.

The action was needed & Fire Security was the clear choice in regards to fire protection cost and fire safety.

Fire Security was contracted to do a test project to protect the splices and nearby distribution cables. Shagang Steel told us they have more than 10.000 spliced HV cables running in the plant area.

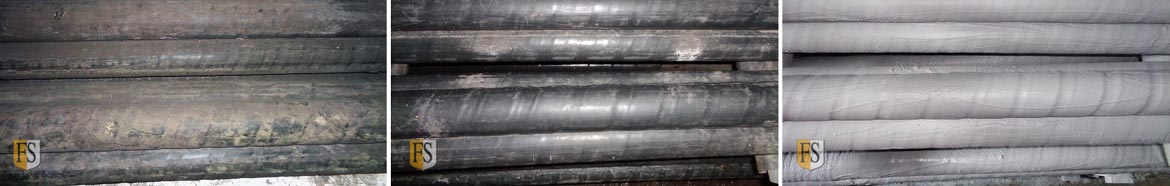

View cable splices before and after cable coating. Fire protection cable coating was performed by Fire Security’s team in China

Fire Protection for underground cable tunnels

The cable protection project took place in an underground cable tunnel where high voltage cables ran in cable racks mounted on the wall. Fire protection services, from Fire Security, protected 60 splices and coated all cables immediately nearby. The distribution cables now have a safety distance of 7 meters to each side of the splices, for a total of 120 meters including the cable racks.

Cables are cleaned with high-pressure water. FS agent Eric Wei is very pleased with the result of the pilot project.

Cleaning cables before cable coating is essential

We spend 3 days cleaning the cables. Fire Security repeated the cleaning process 3 times to remove all dirt and dust collected since 1975.

It is of the utmost importance to clean away all dirt and dust particles to allow good adhesion for the cable coating. With a thorough cleaning, the cable coating will last throughout the warranty period of 7 years and beyond.

Cables before & after cleaning and fire protection coating by Fire Security at Chagang Steel, the largest private steel enterprise in China.

The industrial cable coating process took another 2 days. Fire Security coated the cables twice with FS5 ablative coating to build correct dry film thickness for effective fire protection.

Successful Firestop pilot project finished & more is already planned for this huge steel plant.

Shagang Steel expressed that they were very happy with the fire protection application. Fire Security was pleased to hear that they have already been informed that a second project is already planned for. Fire Security is proud to be the preferred provider when it comes to cable repair, cable life extension, and the highest fire protection rating.

Learn more about fire protection services and cable life-time extension / industrial cable repairs.

Contact Fire Security for more information.[/fusion_text][fusion_text]