Non-disruptive Cable Repair

What is Non-disruptive Cable Repair?

What is Non-disruptive Cable Repair?

FS specializes in Class Approved passive fire protection of electrical cables by way of cable coating. Our applications can be completed on live cables with no disruption to your operations.

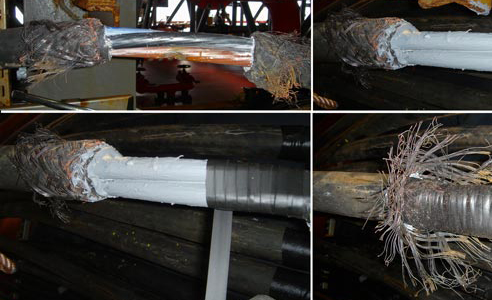

FS repair and coating system repairs cables that have suffered UV, Mechanical, Fire, or Environmental damage to the outer sheaths. Repairing and upgrading these cables eliminates the need for costly large-scale cable replacements.

After manually rebuilding the damaged sheaths and restoring insulation and mechanical integrity with the FS coating and repair system, the cables are protected against environmental stress and further damage. The restored cables are ready to continue service with a warranty backed turnkey application.

Read More

Cable Maintenance Guide for Lifetime Extension

Why Non-disruptive Cable Repair?

Why Non-disruptive Cable Repair?

FS cable repair procedures are tested and approved. We deliver a turnkey solution that avoids operation shutdown, removes the costly need for cable replacements, and halts the spread of further damages. Rejuvenated cables continue their operation with a warranty backed application

We conduct cable repairs and upgrades while the cable is energized when safe and practical, meaning production shutdown is often not required.

The repaired cables will be fully restored as well as upgraded to withstand the environmental issue which originally damaged the cable in addition to fire-technically upgrading the properties of the cables.

Extend the lifespan of your cables

Cables damaged by UV exposure, Oils & Chemicals, Mud, and Ozone become a safety hazard and this is where the FS repair and coating solution is very cost-efficient. FS rebuilds and repairs the outer sheath and armor and then the coating creates a protective new outer layer restoring and upgrading the cable’s insulation properties.

How Non-disruptive Cable Repair Work

How Non-disruptive Cable Repair Work

A site survey is normally required to understand and identify the cable problems, followed by a detailed survey report with suggested solutions. This service is offered with no further commitment from the client. Contact us today for a free online consultation.

Initial contact is normally followed by product presentations and site survey. FS’s experienced surveyors will identify your cable problems and produce a detailed survey report where we document current and likely future conditions of your cables, propose the appropriate repair solutions, and indicate a budget.

Turnkey applications are delivered by our own experienced technicians using only FS Class Approved products and the work process concludes with a full documentation package including Completion Report and Warranty Letter, supported with relevant Class Approvals and Testing.

Cables with cracks in the outer sheath will be individually wrapped with FS repair tape before being sprayed with FS coating to create a new and improved cable sheath.

When water or chemical ingress has caused the cable braiding to corrode, we will remove the damaged section and replace the braiding with FS metal shielding tape before rebuilding a new outer sheath with FS electrical repair tape. FS coating is then applied to make it a class approved permanent repair.

Our repair methodology depends on cable type and technical specifications. But in general, the regulations for repairing cables say “to the same standard or better” than the original.

Videos

Videos

Videos & Brochures

For industrial plants we provide cable repair, cable life extension and fire protection.

You might also be interested in

You might also like

Cable Life Extension

A cost-effective solution to prevent premature or unnecessary cable replacements.

Cable Fire Protection

Passive fire protection by the way of cable coating. Our applications can ble completed on live cables with no disruption to your operations.