Oil & gas companies use Fire Security’s products and services worldwide.

The most important advantages are the increased safety for personnel in the facility, but we also like to mention:

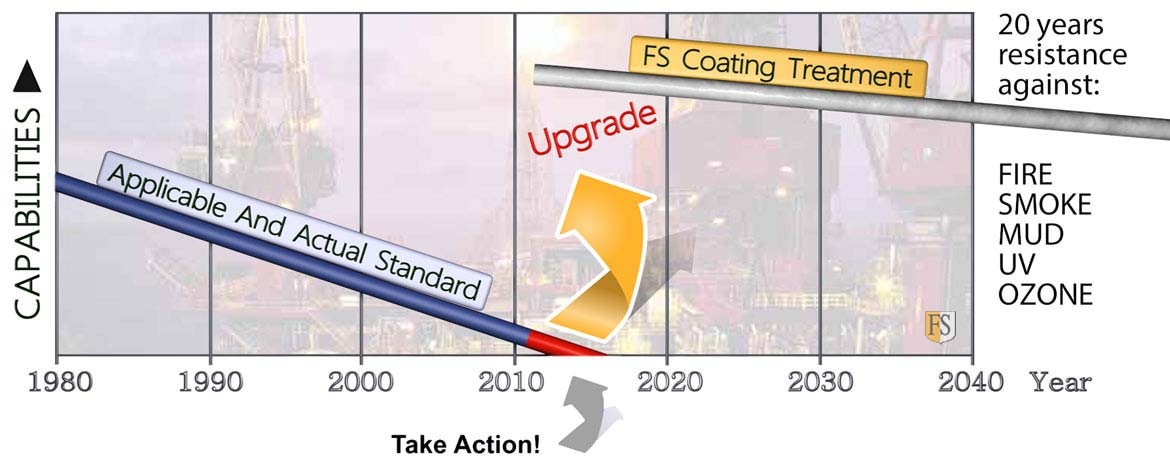

- Life extension and fire technical upgrading of existing cables.

- Increased reliability of existing cables, reduced shutdowns caused by cable failures.

- Prevention of environmental damages to the cables by UV, Ozone, mud, oil, etc.

- Safe operation during a fire incident, control, surveillance, etc.

- Reduced downtime after a fire incident.

- Reduced secondary cost after a fire incident.

Cost analysis differs for each installation. With a survey, the economic effects will be more apparent.

The cost of coating is usually a fraction of changing cables due to the following:

FS cable coating advantages:

- Fire Security is dynamic and flexible with short lead times in supply and installation.

- Fire Security conducts the coating of cables with operation as usual.

- We can adjust the work team to suit the bed space available.

- Work teams are from 2 persons and upwards suitable for the job and the facilities.

- Fire Security performs the supply and installation at a lump sum fixed price.

Cable replacement disadvantages:

- Changing cables involves engineering work, writing of specifications, etc.

- Cables are generally long lead time items.

- Changing cables involves the shutdown of operation.

- Changing cables involves a larger crew to work onboard the facility.

- Changing cables requires re-commissioning of all equipment involved.

- Changing cables carry an inherent risk of schedule and budget overrun.

Comparing FS cable coating to the alternatives – do nothing or replace cables.

Cables are the nerve system of the installations, and the average design lifetime is 20 – 25 years. Cables have a typical warranty of 1 – 2 years. Actual cable performance in terms of age depends on factors like UV, Ozone, Oxygen, etc.

Alternative 1 – do nothing with the cables:

- The advantage of not doing anything is a very short-term cost-benefit.

- In the slightly longer term, the risk of not doing anything is severe and real.

- Postponing maintenance induces a higher risk to the personnel and the whole installation.

- We have experienced premature aging and failure of cables after only four years of operation; more common is premature aging and failure after 10 -20 years.

- After that, cracks appear, and soon, unwanted shutdowns occur due to cable failure and short circuits.

- The risk of fire incidents is dramatically increasing.

- The consequences of a fire are more drastically.

- The cost of operation is higher due to unwanted shutdowns and frequent repair work.

Alternative 2 – Replace cables:

- Changing cables may be preferable if the whole facility is to be re-designed to a different function and must be shut down in any case.

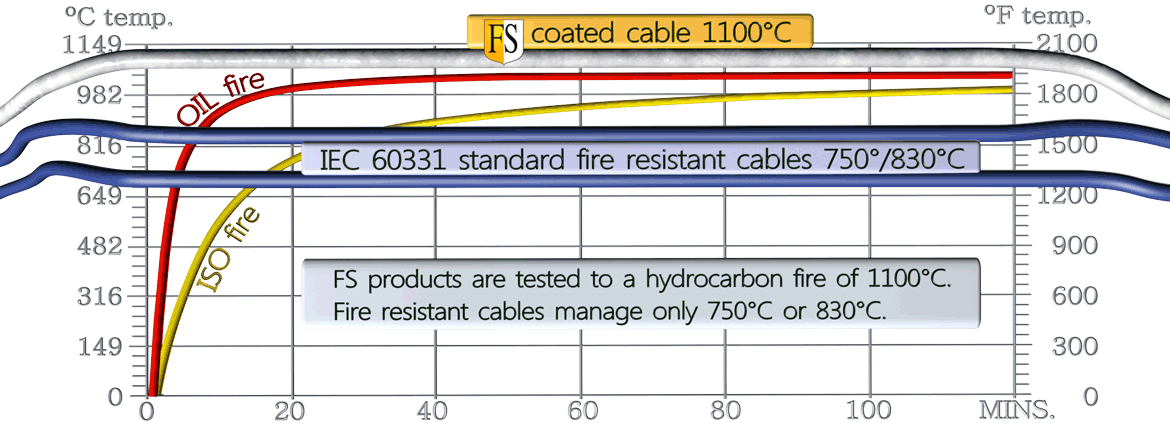

- Still, in terms of fire and risk assessment, flame retardant and fire resistant cables do not match the Fire Security coating in terms of actual fire performance.

- If a fire occurs, the uncoated cables will have to be replaced.

- FS coated cables remain operational during a fire and do not need replacement after the fire incident.

- The cost is considerably higher and involves an uncertain period of a shutdown with re-termination of cables and commissioning work, please refer to the cost section above.

The primary advantage with Fire Security’s coating system is a much higher safety level for personnel and the installation as a whole.

FS coated cables can survive a hydrocarbon fire of 1100° C (2012° F) for up to 90 minutes.

Further advantages with Fire Security’s coating system are:

-

- Regular operation of the facilities during the coating application.

- The highest level of fire safety for cables, with certification.

- The significantly longer life span for existing cables.

- Much more resilient cables in terms of UV, Ozone, chemicals, etc.

- A fixed cost.

The Fire Security coating systems are non-toxic and environmentally friendly during production, installation, drying phase, and after installation. Furthermore, in a fire situation, the coating prevents the release of toxic fumes and gases from the cables. Thus the overall gain in terms of human health and the environment is excellent.

Fire Security operates worldwide in any industry.

Contact FS for a presentation of our cable repair and fire protection solution based on more than 30 years of experience. We also offer on-site inspections and cable surveys, with no commitment from your side.

In addition to representatives worldwide, Fire Security has offices in Norway, the USA, South America, Asia-Pacific, Middle East, South Africa.