There are many benefits to having industrial cable repair services such as:

– Meeting safety standards

– Meeting safety standards

– Reduce downtime

– Increase production

– Improve efficiency

– Reduce risks

– Prolong the operational life

– Good for the environment

Why Electrical Cables Fail?

Industrial cables like High Voltage electrical cables, fail because they get damaged by being stepped on, cut or pulled off their supports by heavy equipment or vehicles and because of different environmental influence.

What are the Causes of Mechanical Damage?

A common cause of mechanical damage is corrosion due to mud, water, snow or chemicals. Moisture penetrates through any cracks in the PVC surface and starts eating away at the metal underneath.

Corrosion causes the metal to oxidize, which can lead to pitting. Pitting is a form of corrosion that creates small holes in the metal surface. It’s not uncommon for these pits to grow into larger holes as time goes on.

On a ship or an offshore installation there is often vessel movement influencing cables, resulting in mechanical damage on cables.

What are the Best Practices for Preventing UV Damage in Electrical Cables?

UV damage is a serious problem that affects the outer sheath. It is caused by prolonged exposure to the sun and other sources of ultraviolet radiation. UV light can cause the insulation on the electrical cables to break down, leading to an electric shock or fire.

The best practices for preventing UV damage in electrical cables are to use a coating that is resistant to the sun’s rays. The introduction of UV protection coating on electrical cables is the most effective solution for the prevention of UV damage. It will reduce the risk of failure in power lines, while also extending the life of these wires and cables.

How to Identify Chemical Damage in Electrical Cables

Chemical damage can take on different forms, but the most common is a whitish or brownish residue that can be seen on the outside of a cable. This residue is caused by chemicals that have penetrated through the rubber insulation and have come into contact with the copper wires inside. There are also other physical signs such as discoloration and corrosion that may occur in areas where there has been chemical exposure.

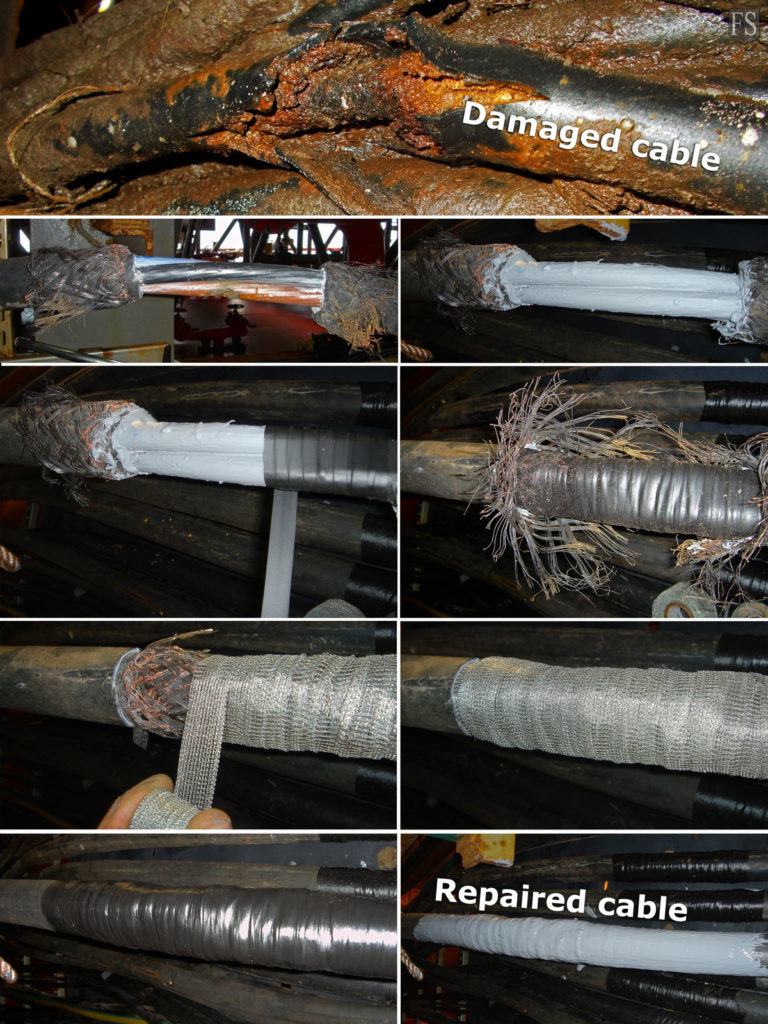

How to repair electrical cables

FS repair and coating systems are used to repair damaged cables. We fix UV, mechanical, fire and environmental damage along with repairing the outer sheath and inner insulation. This can help you save money by avoiding the need for new cable installation.

Our team can fix any type of cable damage by rebuilding the sheath, sealing gaps and restoring insulation. With our FS coating, they’ll be protected against environmental stress and other damage in the future.

The restored cables will be good as new and come with a warranty.

As a bonus, the repaired cables are fireproof due to the coating.