What is a High Voltage cable

What is a High Voltage cable

High voltage is a type of electrical power that is used to run a variety of electrical equipment. It can be found on ships, in factories and in other businesses. High voltage is typically measured in kilovolts (kV) or megavolts (MV). Typical voltage on Medium Voltage and High voltage cables for industrial use are from 12kV, 12000 Volt. This type of power cable is dangerous and should not be touched without the proper training. If you have any questions about high voltage, it is best to contact an electrician for help.

What are the costs of replacing a High Voltage Cable?

The cost for replacing a high voltage cable varies depending on the size of the cable, how many cables are to be replaced, whether the cable route is very complicated, and whether there is an underground power line. It is essential to know that the best practices for replacing a high voltage cable are different from those for other types of cables. For instance, if the power lines are underground, they will need to be capped off and marked so that no one accidentally digs into them. An extra cost may occur if the installation of new cables requires the overall operation to shut down.

What is the cost of HV cable repair?

The cost of cable repair will depend on the length and the number of cables and the type of damages. FS has conducted many projects in different industries, and a broad experience from these projects is that repair cost is very competitive compared to replacement of cables; often clients can save 90% or more. FS repaired cables are as good as new or better and are also protected against future damage. As a bonus, our coatings also protect against fire.

How to repair High Voltage cables

Repairing a cable is depended on the type of cable and the quality specifications. We abide by those guidelines in most cases. However, repairing cables is different from manufacturing them because repairing says “to the same standard or better than the original”. Read more in our Cable Maintenance Guide.

Cables damaged by UV exposure, oils and chemicals, mud, and ozone make for dangerous conditions in your facility. FS repair and coating service is the most cost-efficient option compared to replacing cables. FS rebuilds and repairs the outer sheath and armor, and then the coating creates a protective new outer layer, restoring and upgrading the cable’s insulation properties.

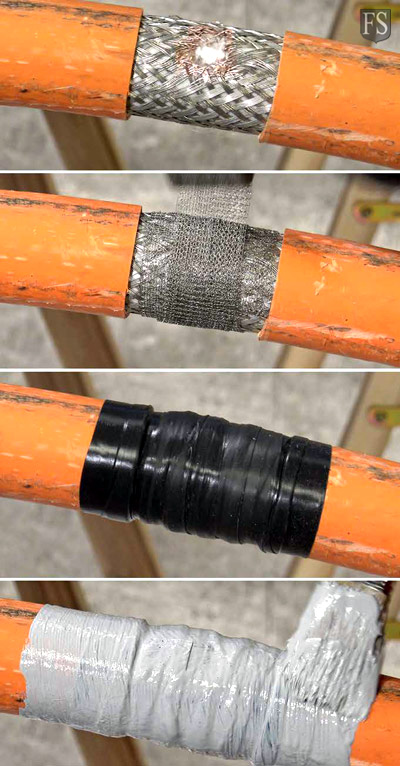

We repair cables with cracks in the outer sheath with durable FS repair tape. The taping process creates a new, strong, and waterproof cable sheath. If the braid is damaged by water or chemicals, we remove the bad section and replace it with FS metal tape on both sides. Then we put a new sheathing on with FS electrical repair tape.

FS coating will be applied to a damaged area after repair to make the object approved for many years of service. Many insurance companies recommend the FS repair program, and it is also approved by leading classification societies and authorities. We call our cable repair method CERTIFIED SUSTAINABLE CABLE MAINTENANCE since it is also better for the environment than replacing them with new cables.

BROCHURES:

Cable repair for onshore industries.

Cable repair for the oil & gas industry.

Cable repair for LNG ships and plants

FS